50 Years of Innovation - The Story of BG Products

This article summarises a book: By Grace: A Story of the Founding and Growth of a Great Company, written by respected BG veteran Edward J. Bash. It is a story of a unique company born from adversity and destined for greatness. Since the founding of BG Products Inc. in 1971, BG has been innovative and responsive in producing extraordinary petrochemical products for an ever-changing automotive industry.

Company Built by its Distributors

Late 1930’s man called Chestien Wynn formulated a revolutionary product in his garage called Friction Proofing Oil. Chestien Wynn was an attorney by profession and started selling his product near his home in Azusa, California. However, it was after the second world war when he began appointing distributors for his exciting product.

Roy Leslie & Bill Kenz with their record winning Streamliner

Over the years and with the committed distributor's Wynns Oil Company grew. Wynns distributors conducted several innovative marketing campaigns to prove the performance claims of the product. Tests like Wynn’s Twin car test (1954) by Kenz & Leslie Distributing Co., Tractor Pull Test developed by Don Broadbent and motor racing with Roy Leslie’s (1957) American record-setting Wynn’s Friction Proofing Streamliner.

“All these tests conducted by Wynn’s exclusive distributors helped create unique identity and awareness of Wynn’s brand in the automotive trade. One of the boldest promotion projects: An aeroplane flew without oil in its engine! This test was conducted by John Thompson and Q.T. Williams with Ed lamb, a distributor in Dallas, Texas. With a great deal of fanfare and publicity, the aeroplane - treated with Wynn’s Friction Proofing Oil - had the oil drained from the engine. Then the plane took off and flew safely for several minutes without oil its engine.” These men besides Ed were all future BG Founders.

Changes in Business Model

A Younger generation of the Wynn family takes over the business and gradually wants to go retail and change the successful Wynns business model from distributors only to retail chains. “First, Wynn’s decided to become a public company, traded in New York Stock Exchange. This created an entirely different atmosphere in the operation. Previously, it had been privately owned, with Carl and Bea Wynn being its principal owners.”

“Second, there was an influx of men from outside the automotive industry who occupied key positions within the company. Third, discount stores grew phenomenally. Stores like Target, Kmart and Walmart sprouted everywhere. Soon, discount stores were selling every known additive product. One of these products was called STP. STP sales exploded within the discount market.” The opportunity to go retail was irresistible.

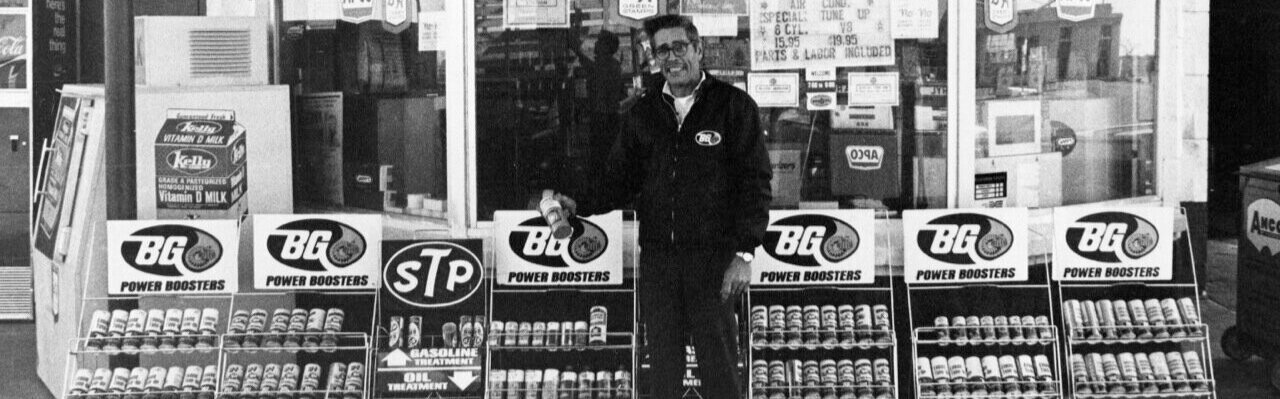

“If there ever were a company built by its distributors, it was Wynn’s.” They had been dealing decades with professional trade only. “Plan of action was that Wynn’s would make concentrated effort to enter the lucrative, high volume, discount market at prices that would be competitive in that market”. Distributors felt the decision was simply unacceptable. “We constantly affirmed that our products were not available in stores at discount prices and “never would be”!” On that day July 1971 called “Chicago Massacre”, ten biggest Wynns distributors decided to arrange a meeting to discuss call of action. Ten distributors broke out from Wynn’s, and 7 out of the ten were brave enough to become founders of BG Products Inc.

They broke out from a solid and safe business to uncertainty without products and manufacturing, just seven territories but nothing to sell. The founding was to become the core value for BG Products. People are important, anybody who touches our product. Even today, BG products are sold by exclusive distributors. It is rare in today's world.

All the original founding families still own the business today, and people like writer Eddie Bash are still with us. It is sporadic these days, and that is one of the reasons how we are different.

Founding BG Products Inc.

BG Products Inc. was founded in July 1971. At the time of the founding, they were without any manufacturing capability. It must have been a stressful time to find a manufacturer to keep business going quickly. So search for suitable manufacturer started. A couple of BG founders Sam Parks and Q.T. Williams were former airforce pilots, so they used aeroplanes to visit several possible facilities.

By chance and opportunity to find a manufacturer presented itself, and a company called Southwest Grease & Oil agreed to start manufacturing newly formed company’s products. At the time, Southwest Grease & Oil was the largest grease manufacturing company in the world. They had a plant in Wichita, Kansas, which is why BG Products headquarters are in Wichita.

Southwest Grease & Oil manufacturing plant downtown Wichita

At the meeting with founder & CEO H.A. Mayor of Southwest Grease & Oil: “They explained their disastrous background and told their desire to manufacture a product line that would put them at the forefront in the automotive additive business. They explained that our products must be of the highest quality, designed especially for professional use market. Mr Mayor related to a similar experience from when he was younger, and with that, he rose from his chair, pounded his desk and shouted, “Hell yes, we will make products for you!”

Cornerstone no. 2 was set. We need to carry extensive R&D to remain at the forefront and carry the highest quality products. Today BG Products has around 60 people working on laboratory, product prooving and testing.

How do you sell high quality products?

The manufacturing had been agreed with Southwest Grease & Oil. The next question was; how do we sell a high-quality product, which is entirely new for the market? “We had to dig in and sell BG products and earn our niche in the marketplace with BG. Our early years in the marketing of BG products were bittersweet. Exciting and exhilarating and at the same time very tough.”

“It was essential that we get our salesmen trained.” So, with the help of Southwest Grease & Oil personnel, salespeople started getting training about the basics of lubrication, fuels, gear lubes and the newly formulated BG products.

The need to train and arm our people with better knowledge became an essential part of our way. Today training is ever so crucial with technology developing. It is so important that we have our very own division focused on training. We don’t just train our people; we train our partners to understand how products work and how they should communicate with their customers.

First Two Products

The first-ever products from BG were called BG Super Charge® and BG Engine Tune-Up. Supercharge was a petrol fuel system cleaner and Tune-up an engine oil additive. The more developed successor Super Charge® II is still being sold today.

BG Super Charge® original design

The need to demonstrate product efficacy was needed to sell these two new BG products. Eddie; “An essential for me was to take the basic information about the products and create effective presentations and demonstrations for BG salespeople.”

Demonstration of product efficacy was needed, and Eddie was tasked to come up with demonstrations. “You would pour about an inch of gasoline and then add a drop of sulfuric acid into a test tube and rotate. By rotating the test tube, the sides of the tube would be plastered with heavy brownish red varnish. The addition of about half-inch of BG Super Charge® to the mess would clean the tube and put all the varnish back into solution in the gasoline. It was beautiful. That demo, with many technical additions and modifications, has been used for our entire history in the sale of clean up and keep-clean BG fuel additives (with great success).”

At BG, it was and still is very important to show quality and the results in a transparent way. Transparency is the key for us to keep integrity and professional credibility.

The 100.000-Mile Story & Oil-Less Engine

Over the Years, BG founders had performed adventurous products demonstrations, like flying an aeroplane without oil, just a little bit of friction modifying additive. If you ever have heard these automotive product demonstrations, these men have most likely been involved.

Shortly after the introduction of BG MOA®, Q.T Williams began to test it with his new Pontiac Station Wagon. “This was to be a 100,000 mile test. Throughout the duration of the test, he changed the oil every 3,000 miles with BG MOA® added to new oil. BG Supercharge® was also added with each fill-up of gasoline.

After the 100,000-mile test was completed, Q.T. returned the car to the Pontiac dealer from whom he had purchased the vehicle. He arranged with the service department to perform a complete engine tear down and to “mic” all of the engine components to determine how much, if any, wear had occurred.

The results were startling! No measurable wear anywhere in the engine. The cross-hatching was still in the cylinders! No evidence of any deposition in the ring land area. No deposits anywhere in the engine! Upon measuring: bearings, no wear; crankshaft, no wear; camshaft, no wear; lifters, no wear; rod bearings, no wear. All of this process was photographed with a 16 mm movie camera.”

BG Oil-less engine was revelation at the time.

“It was also Q.T.; Who built the first oil-less engine. To demonstrate it, you would start it and let it run for few minutes. Using the extension of a jack - that was welded to the bottom of the pan - you lowered the pan containing oil to a point well below the turning crankshaft.”

“I can’t even begin to assess the value of the oil-less engine in helping us build the business during our early years and beyond.” Even today, the oil-less engine is actively used.

BG has since performed multiple long-term vehicle tests to provide further proof. Every professional back then and today want to see results in their own eyes. It is our pride and joy to show these great BG products and to see all those happy faces days in and day out.

Crippling Loss

“During the most of the following the formation of BG Products, Inc., Roy Leslie (one of the founders) had been battling a series of severe health issues, the most serious being advanced Colon cancer. Unfortunately, on September 10, 1973, Roy Leslie passed away.”

Roy Leslie had a long history as a Wynns distributor. Later, one of the founders of BG Product Inc., Kenz & Leslie distributorship had played a prominent role throughout the early years of BG Products and later.

Roy Leslie and his Midget racing car.

“Former auto mechanic Roy Leslie partnered in business and racing with longtime friend Bill Kenz—the Kenz & Leslie parts business in Denver, as well as a streamliner of the same name that set records on the Bonneville Salt Flats. He had set a new world’s land speed record and had the quickest speed on record for an American driver in an American car. Roy imparted the integrity and virtue of an honourable businessman.” - SEMA hall of fame

“Later that year, on a Saturday evening November of 1973, I got a phone call from Don Walton. Eddie, he said somberly, I've got some bad news. John Thompson (one of the founders) died in a heart attack this afternoon. It was like I had been kicked in the stomach. John was a picture of health. He was an airforce pilot during World War II, who had been called for duty during the Korean War.”

Two of the founders passed away in a short period of time, during the critical early years of a fledgling company. “Both men were astute businessmen who contributed greatly in the founding of infant BG Products, Inc.” Their families continued their work with John Thompson wife Nell and shortly after her son John took over. Roy Leslie's son Ron taking over his fathers business.

Even today, these families own, operate their distributorships and contribute to BG Products Inc. Despite all the difficulties and years gone by, families have stuck with BG. It is an extraordinary story in today's world and a profoundly different background to any other businesses in the automotive industry.

Reaching Out

Exclusive distributors have always distributed BG Products. However, back in 1974, they did not have many of them.

“In December 1974, Don Broadbent (one of the founders) and I made one of the most significant sales presentations ever in furthering the distribution of BG products.”

Don had called up a meeting with Purolator (PCP) distributors in the Northeast. They met up in William Penn Hotel in Pittsburg. “As a result of meeting Larry Rosenthal, Pete Edwards and LeRoy Siegel signed on as BG Distributors. To that point, we had no distribution of BG products in the northeastern U.S.”

“After our sales meeting, I spent time conducting clinics with LeRoy and his staff. The next week I got a phone call from dejected LeRoy telling me that all but two of his salespeople had defected and had become PCP distributors. It cost him dearly to sign on with BG. But, with guts and pure dogged determination, he built one of the top BG sales organizations in the nation.”

These men like Leroy Siegel and Pete Edwards have stayed with BG Products and seen the company's phenomenal rise, with so many other additive companies going bust or just simply fading away.

Committed sole right distributors in each geological areas, not a bad model for business.

Boom to Bust

“Oil shortages, which began in 1975, created an entirely different environment in everything from manufacturing to marketing for BG Products, Inc.” There were shortages of gasoline, and crude oil prices were escalating. “This started to began to affect the price of nearly everything, from plastics to anything else that was petrochem.”

“BG products changed so rapidly that the distributors often faced new price quotes each time they ordered.”

“But, around every cloud, there is a silver lining. With the crude oil drilling industry rising to dizzying levels, a long-dormant U.S. oil drilling industry went into high gear. Drilling rigs couldn’t be built rapidly enough. So feverish drilling began in Louisiana, Texas, Oklahoma, the Rocky Mountain region, California and many other areas of the U.S., including Alaska.”

“For the enterprising distributors who operated in these areas, all this activity signalled “opportunity.” Some BG distributors started selling large volumes to drilling companies, and with that cash flow, they were able to survive. However, it took a lot of learning because this was a new business area for BG salespeople.

Research & development lab back in the day

This period was said to be the catalyst for significant development in the automotive industry. Emissions and fuel consumption was to become a point of sales for new motor vehicles. This meant changes to the fuel systems and emission control. Devices like the catalytic converter and fuel injection system were about to hit the market.

The dynamic and inventive businesses survive and strive in these challenging times.

A Big Change and a Huge Opportunity

“In the life of BG Products, Inc., an earth-shaking event took place in 1977. H.A. Mayor, the founder and owner of Southwest Grease & Oil Co., the largest grease manufacturing company globally, took his own life. Faced with incurable, inoperable cancer, he ended his life with a single gunshot. This man who, upon hearing of the dilemma facing a tiny group of ex-Wynn’s distributors, pounded his desk, claiming, “Hell yes, we will build products for you!”

H.A. Mayor and his company had helped BG Products, Inc. to become a reality. Upon his death, Southwest Grease & Oil Co. was transferred to his son, Sonny Mayor. Sonny Mayor did not have the passion for continuing his father’s business. So 1978 company called Witco bought Southwest Grease & Oil Co. Witco was a large company that manufactured motor oils and other chemical products and brands such as Amalie and Kendall. They named the company Southwest Petro-Chem.

“With all of the change occurring, Don Walton (one of the founders) negotiated with Witco on the possible purchase of their Plant 3, downtown Wichita. This building had been re-designed to manufacture, package, warehouse and ship petrochemical products, including BG products.

“BG Products, Inc. became a real business entity. In possession of all of our operation, we could control BG’s destiny.” With the purchase of Southwest Petro-Chem Plant, 3 BG Products Inc. had become a petrochemical manufacturer.

A Tale of Two Young Men

Many people at BG Products have made BG a lifetime career. It is extraordinary these days.

“1984, A bright young man who had worked a territory in Colorado Springs came to me with the news that he would be leaving K&L (distributorship in Colorado). Instead, he wanted to join another distributorship in Atlanta. “Darin Greseth, at the age 19, was the youngest man I had ever hired as a salesman.”

Darin Greseth later became a distributor in absolute resolution for BG Products in the state of Michigan. “Darin has absolutely mastered every facet of the operation of a BG distributorship.”

“In that same bubble bursting year, I interviewed another significant young person. Charlie Polston had just graduated from Oklahoma State University. In June 1983, Charlie started his career with BG Products in Denver, Colorado.” Needless to say, he has been hugely successful in selling BG products. But that was not all Charlie has done.

“Charlie has served hugely in the overall growth of BG Products, Inc. Not only has he been helping to build one of the strongest distributor ships, but also he has been the “premier trainer is salesmen and distributors for BG Products, Inc. Throughout BG University (BGU), hundreds of BG salespeople have grown in the basics of sales through Charlie’s Boot Camp.” Charlie Polston is one of the most respected fixed ops trainers in North America. He is a regular columnist for Dealer Magazine and Auto Inc. magazine and frequent workshop leader in NADA conventions.

One more thing: In 2010, Darin Greseth was appointed the President of BG Products, Inc. He is still serving BG Products, Inc. in that role today. BG Products, Inc. has grown a dominant player in the North American automotive sector in his watch.

Lifelong careers with BG, pretty cool. Company President who knows what is needed in the front line of our business, quite remarkable for any business.

Oh Happy Days!

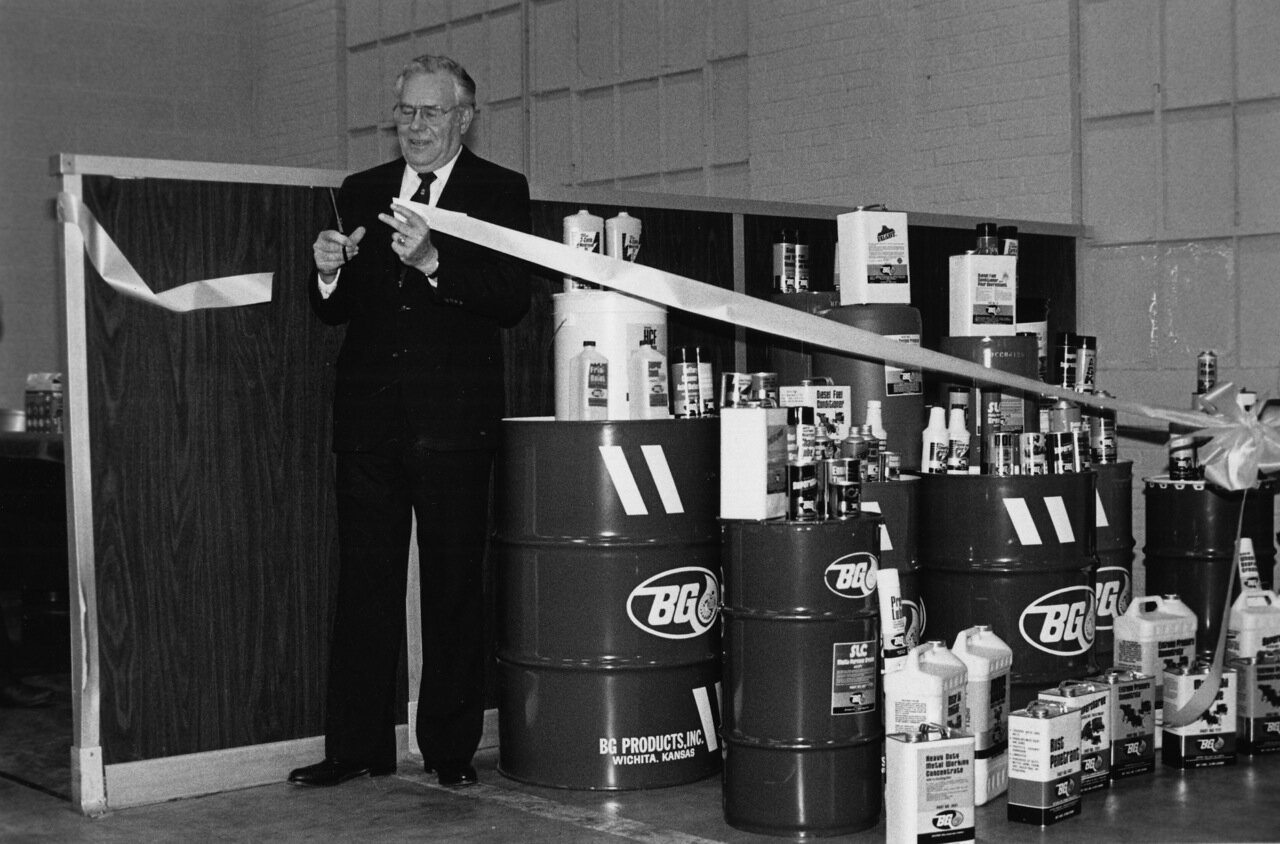

President Don Walton cutting ribbon, at the time of the grand opening.

“After several months of negotiation with Southwest Petro-Chem (Witco), the purchase of Plant 3 was signed, sealed and delivered on January 31, 1986.” It took quite many years that the previously negotiated “right of first refusal” for the purchase of Plant 3 became a reality.

“From such a humble beginning, we had scratched and clawed, picked ourselves up, dusted ourselves off and went right back into the fray.”

“Joining the eight plant employees were four women who already worked in our office. BG Products, Inc. Now employed a total of 12 people. Wow!” That was 1986.

Today BG Products, Inc. employs a total number of 375 people. Majority of them working in production, research and product development.

Condemned!

“In 1987, A letter from the City of Wichita delivered the news that our recently acquired property was being condemned in accordance with rules of Eminent Domain.”

“BG Manufacturing facility stood on ground that that was needed for building a highway exit. For our property and buildings, BG received an insulting one million dollars, which according to city, was assessed value.”

This caused anxiety and would be a devastating blow for BG and its distributors. It would not mean losing production facility, but it would also seize all operations.

“After protracted negotiations with the city, partial surrender of land was agreed upon. For this, the city would pay for enlarging the remaining building and refitting the entire manufacturing facility at the cost of $3.97 million.”

“Across the street, on the east side, the city had condemned property belonging to an auto detail facility. We were able to acquire that. We refurbished the remaining portion of their building, which became our innovation centre.”

That unfortunate action led BG to further their testing and proving. BG Innovation centre has since been replaced by a state-of-art facility: BG Technology and Training Center is home to the BG Proving Ground, a facility dedicated to hands-on automotive research, development, testing, and training. The new, larger facility has allowed the BG Proving Ground team to grow and expand and continue to push the envelope for automotive excellence.

We Owe Lot to our Founders

Seven Original BG Products Inc. founders Don Broadbent, Don Walton, John Thompson, O.J. Connell, Q.T. Williams, Roy Leslie and Sam Parks

“It is only natural that when men take a risk and make an investment in starting a business that they want to receive and enjoy rewards for their success. Yet, not one founder ever received any appreciable financial return. Instead, such was the commitment they dreamed of building that profits ploughed back into creating a fiscally strong company.”

They built a company that could purchase property, build buildings, upgrade production lines and expand warehousing. Today’s improvements are because of yesterdays commitment.

“Business success is in direct proportion to the service rendered.” It means that we cannot succeed with an attitude, “What’s in it for me?”

“Our founders understood that our people were our greatest asset. So we created products and services designed to help our customers succeed.” Training our salesmen on BG products came more to the front as we grew.

“I’m firmly convinced that this respect for our distributors and our willingness to invest in them has helped create the unique BG family.”

“As you sow, so shall you reap.” So we put our customers first, give them our best and hope that we will reap the best—the culture set by our founders instilled in this great company called BG Products.

Fuel Products Boom

“In 1984, the “Big Three” domestic vehicle manufacturers (US) introduced multi-port fuel injection and throttle body fuel injection systems on many of their models. By 1985, nearly all automobiles, regardless of engine size or design, featured electronic fuel injection systems. Along with fuel injection came much computerisation-much more finely tuned engines. All these changes were designed to help achieve perfect 14.7:1 air to fuel mixture introduced into the combustion chamber at the point of combustion.”

“But for some reason, as these design changes were being created and tested, OEM Research and Development (R&D) was unaware of possible negative consequences from the use of petrol available in the marketplace.”

“The dealer service technicians didn’t have answers. But, unfortunately, neither did OEM service reps.”

Worlds first ever fuel injection system and air intake cleaning tool BG 9210 VIA.

This technology change in the automotive industry started a process within BG that would lead to the development of one of our standout petrol fuel products. It is very core of BG Products business model. However, our professional only customer base needed results, and so we began to dig for answers.

After some experiments, BG Products Inc. introduced the worlds first aerosol fuel injector cleaner. “For quite some time, we sat alone in the catbird seat with a tool and material that would allow a technician to solve his biggest drivability problem. However, the use of the product revealed some shortcomings in the formulation. BG Carburetor Cleaner didn’t do the job on some injectors.”

“Galen got to work on adjusting the formula by adding BG Supercharge® to a cleaner that could run the engine. It proved to be much more effective than BG Carburetor Cleaner. Soon BG introduced an aerosol fuel injector cleaner with BG Supercharge®. However, this opened the floodgates, and other aerosol fuel injector cleaners quickly began to appear.”

BG 9210 Inject-A-Flush was then invented to create a small, user-friendly, inexpensive and versatile fuel injection system cleaning service. It was the worlds first fuel injector cleaning tool, and it was exclusively made for BG Products. Unfortunately, at the time, BG could not manufacture the device.

It was the first BG maintenance service and the first-ever BG service tool.

A Star is Born!

In the early eighties, a particular SAE technical paper was explaining new additive technology that would clean hard carbon from intake ports, valves and combustion chambers, as well as fuel injectors. This nitrogen-based additive was driven by European manufacturers having problems with upper engine deposits. BMW intake deposit test ASTM D5500 was developed to measure the quantity and effectiveness of this chemistry.

This very same information became BG’s attention. The cleaning results before and after were shocking. The problem was that this additive was hugely expensive. It would raise our prices to another level, so the resistance among BG Board was understandable. “We would never sell a product that expensive to put in fuel.”

BG 44K® original design

“When we began to make plans for producing the new product, we discussed naming it. At last, I suggested that, since it’s so expensive, let’s name it 24K. Its price is like pure gold. Unbelievably somebody owned the name. Don Walton suggested, “why don’t we call it 44K.” That name stuck, and it became the signature product for BG.

Over the years, BG 44K® has had multiple updates, and today it is called BG Platinum® 44K®. It is one of our “crown jewellery” products, and it just keeps delivering.

The 300,000-Mile Test

“Dennis Rosson conducted the most significant field test ever produced.”

Engine after 300,00 Miles

“BG purchased a 1993 Mazda MX-6 with only sixteen thousand miles on an engine known to have significant drivability problems caused by fuel deposits in the intake system, and particularly, hard carbon deposits in the squish area of pistons. Additionally, the engine showed tendencies to build engine sludge.”

“The Mazda was purchased because of these known problems. The intention was to conduct a 100,000-mile test, using BG MOA® in the crankcase and BG Supercharge® in each fuel tank. The oil was changed with 6,000-mile intervals. At the end of the duration, the engine was absent of any wear or deposit buildup.

Tools & Equipment

From the mid-eighties, BG Products had started to play with tools and equipment. The need from the field representatives was clear; the tools needed don’t exist, and we need to create them in-house. At this time, BG tool ”division” was a one-man show, and that man was called Harold Erwin.

”Transmission flush machine was showing up in some California Dealerships. They were large, cumbersome machine that was not user friendly at all. In addition, it required constant monitoring of a rather lengthy procedure.”

”A prototype of a smaller footprint, the easier-to-use machine was developed by Harold Erwin. While there was a need to test the unit, the distributors wanted the product ”yesterday”, as we always do. The service kit that we determined to use was a product for a clean up and the addition into the new fluid of our existing transmission conditioner.”

The results using new tool and service kits were phenomenal.” After our demo service was completed, we climbed into the car with the tech and went to a test drive. The results were totally unexpected. ”You know, this transmission isn’t slipping anymore, the tech explained. He continued driving, stopped the vehicle, started back up again; he did everything he could to make the transmission slip. It wouldn’t cooperate. It would not slip. He was amazed, and so was I.”

BG PF5 in a Quality Control

”In 1997, we attended the National Automotive Dealer Association (NADA) convention shortly our decision to market the BG PF5 transmission machine. Here was a never before seen, compact, small footprint, a user-friendly unit that required no electrical power, no monitoring, and could easily be moved around the workshop. But, of course, the guys with slick hair and alligator shoes from a particular familiar competitor were all over it. Unfortunately, before the NADA convention ended, someone had stolen the instruction manual for the PF5. I wonder whom?”

There were some challenges with quality and operability, and that all was on the shoulders of one man. ”This tool business is killing Harold.” So it was time to start investing in the tool business.

BG Products Inc. started hiring more people in the tool business, now a viable part of the BG business. It was the beginning of a BG Tool & Equipment division, which nowadays carries AS9100 certification required to provide products for the aviation industry.

The Birth of BG Automotive Maintenance Services

“BG PF5 transmission fluid exchange machine along with a series of high-value services thrusts us into an entirely new position within auto service facilities. They increase labour hours, hours per repair order, workshop efficiency and effective labour rates. Value-added services that made a difference came into focus. In rapid succession, BG introduced truly unique services that addressed lubrication and fuel system requirements, which had been largely ignored.”

“Without superior chemistry, we would be run-of-the-mill. However, BG’s greatest assets are people with integrity and our commitment to creating the best products possible. This is the core of BG Products, Inc. Let’s never forget it.”

Many BG sales reps have played their part in inventing new BG tools.

Ingenious two-way control block, protected by patent.

Bob Knorr invented a user-friendly power steering fluid exchange system. Our subsequent testing in our auto lab showed that, on average, it removed 87 per cent of the old fluid.” That simple but effective tool is protected by patent.

Rick Biasioli invented a little crank tool to install BG’s range of A/C products into the air condition system.

Jay Erwin and the tool division created the BG PF9 brake service machine. They also designed cooling system service equipment CT4 and CT2. “And, of course, at the core of this service is superior chemistry.”

Today BG fluid maintenance services cover all automotive fluid systems: brakes, cooling system, driveline, transmission, A/C, battery, emission system, fuel and engine.

Dennis decided to extend the test an additional 200,000-miles using BG Hi-L0W30, a fully synthetic engine oil formulated with BG MOA® chemistry, during the final 200.000-miles. The oil change interval was 15,000 miles.”

The results were startling, as indicated by components measured photographed after a complete teardown of the engine. Components were photographed untouched, exactly as they were when the teardown was completed.

This test led to innovation—monetary protection against failure of vehicle components that receive BG Services on a prescribed schedule. Stay tuned for the next episode.

BG University 1999

You would think that most companies are doing the right thing for their customers. Maybe they do, what is suitable for the company, but what is right for a business is not necessarily best for the individual. Doing the right thing is not always easy. For BG Products, the equipment and vehicle owner is the customer, and our products and services are ultimately designed for them.

BG University was founded in 1999, just before Millenium. BG University is an ambitious effort to raise the knowledge among the BG sales force to another level.

BGU Training facility

“BG Products Inc., is determined to educate automotive service professionals about the importance of vehicle maintenance and the incredible value of BG Automotive Maintenance Services. This goal led to the founding of BG University (BGU) in 1999.”

“BG offers automotive professionals a unique first-hand experience with automotive technology and an insight into the thinking behind BG Products. Courses are practical and to the point, ranging from basic chemistry to the complexities of the latest advances in engine design.”

“An essential for me was to take basic information about the products and create effective presentations and demonstrations for BG salespeople.” Eddie Bash

Privileged BG Service Partners get first-hand and on-point training provided by BGU across the world.

21st Century - Trials and Triumphs

“The twenty-first century’s first decade could rightly be called a decade of trials and triumphs. Year's of uninterrupted growth was to continue at an accelerated pace during the initial year's of the 2000s.”

This was a decade of continuous innovation:

2003 First to market a combustion chamber decarbonising system.

2004 BG Inject-A-Flush for diesels introduced

2004 BG VW Diesel Air Intake and Exhaust system cleaner introduced

2004 BG Protection Plan ® introduced

2005 First to market a diesel solution to clean when sulphur (cleaning agent) was minimised in diesel fuel.

2007 First to market with a diesel induction system service.

2007 Developed a revolutionary product to clean severe engine sludge together with Volkswagen. Dynamic Engine cleaner gets VW approval.

2007 BG Introduces BG Universal Frigi-Quiet, A/C compressor oil /dye

2008 BG introduces Headlight Restoration kit

2008 BG introduces Universal CVT Fluid

2008 BG Introduces Biodiesel Fuel Conditioner

2008 BG Introduces Air Mass Sensor Cleaner

2009 First to offer a Lifetime BG Protection Plan® for vehicle owners.

2010 First to market with a viable solution to the inherent carbon deposit problem that plagues GDI engines.

“This was followed with great stress and turmoil during the final three years of the decade. Following the collapse of the housing industry and the chaos in the banking industry, the U.S. vehicle manufacturers were on the verge of bankruptcy.” Within BG, the events that took place was first felt as the potential customer base was diminished. But looking back it created unexpected market potential.

Dealerships we're forced to start looking something extra for their service department. This opportunity catapulted BG in to new heights in dealership operations. That growth has continued to the following decade. Today BG is major provider of all fluid maintenance services in North American Dealerships.

For BG Products, this decade was time of great loss by losing the remaining founding members. O.J. Connell Jr., died in early 2000 for a heart attack and BG Products founder, long time president and the Chairman of the Board, Don Walton, and his wife Mary Beth, was killed in a car crash. Before the conclusion of the decade, the three remaining founders had passed on. Sam Parks died of complications related to Alzheimer's disease. Q.T. Williams succumbed to Alzheimer’s in 2009. Don't n Broadbent, the last of the seven founders, went home in 2010.

BG Protection Plan Introduced

Over the years, BG had conducted several long-term tests with its products & services, and the proof was evident. Many other companies followed BG’s lead and made similar kind of claims as BG. Often those promises were without reliable evidence or results. Why not offer monetary protection that would make us different from the rest?

In 2004 BG introduced monetary protection against failure of vehicle components that receive BG Services on a prescribed schedule. BG Protection Plan was aimed to reassure dealership customers that our claims are valid.BG Protection Plan was initially limited for km’s but was later extended for the vehicle's lifetime. Because of this program was renamed to BG Lifetime Protection Plan.

Original Protection Plan logo

The introduction of BG Lifetime Protection Plan (2009) and the momentum in North American dealership occurred around the same time. This was the period of financial turmoil in the housing industry that quickly spread to vehicle manufacturing and vehicle sales in dealerships. In hardship, dealerships started looking at their only revenue generator, The Service Department.

Offering customers an added value service with a transferrable lifetime monetary coverage started gaining ground. This was the beginning of a new era. At the time, BG Products market share in North American dealerships were 19% in fluid maintenance services, according to an independent third-party market research company.

Emphasis on Exports

BG Products started exporting its products to the international market at the turn of the Millennium. “First International Sales Conference was held in 2004, in Wichita.”

“The forming of BG International Trade Operations (ITO) was significant in the decade of 2000s. For the first time, exports were to become an organised entity.” BG ITO has a Managing Director, Market Managers and staff with purpose, direction and full support.

Today BG Products are sold worldwide in places like Japan, Nepal, Israel, Chile, Mexico, Indonesia, China, Russia, Korea, Middle East and all over Europe, to name a few. Over the years, BG ITO has grown into an extended international family. Challenges with modern automobiles everybody faces are somewhat similar, and nowadays people move even countries. The change of information and market experiences are valuable currency.

Over the years, BG’s international reputation started to spread, a brand that delivers. Work with European OEM’s like Volkswagen, Jaguar & Land Rover paved the way. With success in Europe, the word spread to Australia, and finally, in 2009, BG Products were introduced to the Australian market.

Today BG Australia is a well-established business. We have operations in all states, and our growth is continuing at a stunning pace. We have stock-in-hand all over the country and trained people ready to help our partner workshops locally. Products have gained a reputation for delivering results beyond expectations.

New Plant El Dorado

“Throughout the first decade of the twenty-first century, the BG board of directors was deeply involved in planning for the expansion of our plant. Galen Myers, President at the time, spent a great deal of time negotiating with homeowners located to the south of our plant. Our first thought was to expand adjacent to our existing facility. With this thought in mind, we purchased a large amount of property for the purpose. As time went on, it appeared that a better course of action would to relocate the entire plant.”

“City of El Dorado provided a considerable amount of ideally located property to BG at a fair price. BG added the purchase of adjacent land with rail access. This was key in maintaining lower freight costs on incoming raw materials.” El Dorado Plant finally opened up in 2009.

Sitting on 40 acres in El Dorado, Kansas, are BG’s Manufacturing Facility, Distribution Center and Tools & Parts Warehouse.

“BG’s custom-built, one-of-a-kind manufacturing facility spans the distance of three football fields and is where high-quality BG products are manufactured, packaged and stored. Two tank fields with a capacity of nearly 3,4 million litres.

As one of the largest dedicated suppliers of automotive fluid maintenance products and services in the world, we’ve got to have plenty of room to store raw materials and finished product.

Several production lines are suited for as little as 30-mil litre bottles to as much as 1200-litre totes! Whether filling hundreds of thousands of cans per shift or packing nearly 100 kits per minute, each line is built for optimal efficiency and speed.

The full customised plant control system ensures carefully calculated blending and fluid transfer from rail car, tanker truck or storage tank to the filling lines. Automated control for the facility means quick and exact operations with little room for error. The automated Batch Blender system includes blend vessels, and the Continuously Metered Blender delivers components at 150 gallons per minute to a finished product tank!

Training to be Great

“BG Products Inc. were born from adversity, and BG founders nearly saw their businesses collapse. People are our greatest assets, and are valued and respected. Our customers will receive the highest quality products possible. The motorists would, in turn, receive value and benefit for investing in BG Products.” We guarantee our promises with BG Lifetime Protection Plan® a free monetary coverage.

Training has always been necessary for sales of BG products. Not just explaining what we are and what products do, but most importantly training together with customers we develop their understanding of their own business. It is a true form of partnership. Every customer, big or small, is offered the same opportunity.

This commitment to excellence helped BG to grow in the North American dealership market. In 2012 independent study concluded BG Market share reached 22%. The same survey concluded what we already knew. BG 44K® was preferred 4 to 1 over the next aftermarket fuel system cleaner. The most used professional-grade fuel system cleaner in the market.

Some innovations in the first five years of the decade:

2010 BG receives soon to be introduced brand new Ford Taurus with a 3,5 litre Ecoboost GDI Engine; test runs for two years BG Fuel Test

2010 New GDI cleaning cleanup solution

2012 BG Certified Service Advisor online training introduced

2013 First to market a product to protect engines from the harmful effects of ethanol-blended fuel.

2013 New product for cleaning High-Pressure Common Rail diesel fuel systems DFC Plus HP

2013 New BG PXT Power Steering & Transmission Exchange Machine

2014 BG receives ISO 14001 for Environmental Management

2014 Universal Coolant introduced

2014 GL-5 75W-90 High Performance Gear Lubes introduced

2014 First to market with a diesel service designed to clean and improve the smart exhaust system, including DPF.

By 2015 BG had become a coveted brand in dealerships. In the 2015 study, BG’s market share had reached 31%.

The Building Years

To keep up with our fast-paced growth, in 2016 BG commissioned an expansion to our El Dorado facilities. This construction project added 11,148 square meter of warehouse space to the El Dorado distribution campus. Once construction of the new building was complete in, the old distribution centre was to be reconfigured as a kitting facility.

The new BG Technology and Training Center, a new 3158-square-meter facility was opened 2019. The new building features a state-of-the-art chemistry lab and automotive testing facility, home to the BG Proving Ground. It also includes training and demonstration rooms for BG University, our in-house sales training program.

While great things were accomplished in the old building, it was definitely crowded. In fact, our former R&D building, including chemistry lab, offices, storage, a blending room and a secure place for flammables, was only a total of 334 square meter. The lab was sometimes bottlenecked and we didn’t have additional space for more staff to help keep up with our workload.

The new building has 236 square meter dedicated solely to testing. That’s not including the offices, blending room, storage room, and flammables storage. This upgrade has enabled BG chemists to increase the number of testing options and to add several new lab instruments to the space.

2016 Purchase of a robotics company making BG Tools and equipment

2018 BG Platinum Fuel System Service introduced

Market Share Survey

In 2018 two independent third-party surveys concluded what was already quite obvious; BG Products scored it’s highest ever market share in North-American dealerships reaching up to 53%!

This growth has allowed BG to step up from manufacturer to a complete powerhouse for Automotive Aftermarket. In the last five years, BG Products Inc. has built a new campus for R&D, introduced several mobile apps and continued to introduce new products at a tremendous speed.

Some of the latest landmarks at the end of the decade.

2019 Rev-it® tool Automated tool for induction service

2019 Hybrid Performance Service

2019 BG Experience ™ Augmented Reality

2019 New Technology and Training Center

2019 New Eldorado Distribution Center

2020 BG Receives ISO 17025 for Laboratory operations

March 2020 BG Products Inc. made an important announcement, our research and development laboratory is now ISO/IEC 17025:2017 certified!

According to ISO: This standard helps facilitate cooperation between laboratories and other bodies by generating wider acceptance of results between countries. This is crucial to BG as a global company because test reports and certificates can be accepted from one country to another without the need for further testing, which, in turn, improves international trade.

“We’ve always stood solidly behind our ability to administer proper testing procedures and present accurate data,” said Dustin Willhite, Director of Product Technology. “This standard further proves that fact.”

The following certifications and associations require internal and external audits. They are a testament to the dedication and focus BG invests in remaining the unquestioned leader in quality and performance when it comes to vehicle maintenance.