What happens to deposits?

Some mechanics have encountered a poor experience when using chemical cleaners. Others don’t believe in their efficacy and that using them may void a new vehicle warranty. If these cleaners (additives) work, why do some yield no results? If they don’t work, why are they so heavily implemented in the automotive industry? The answer may be true in both cases; let’s look at chemical cleaning in depth to illustrate how.

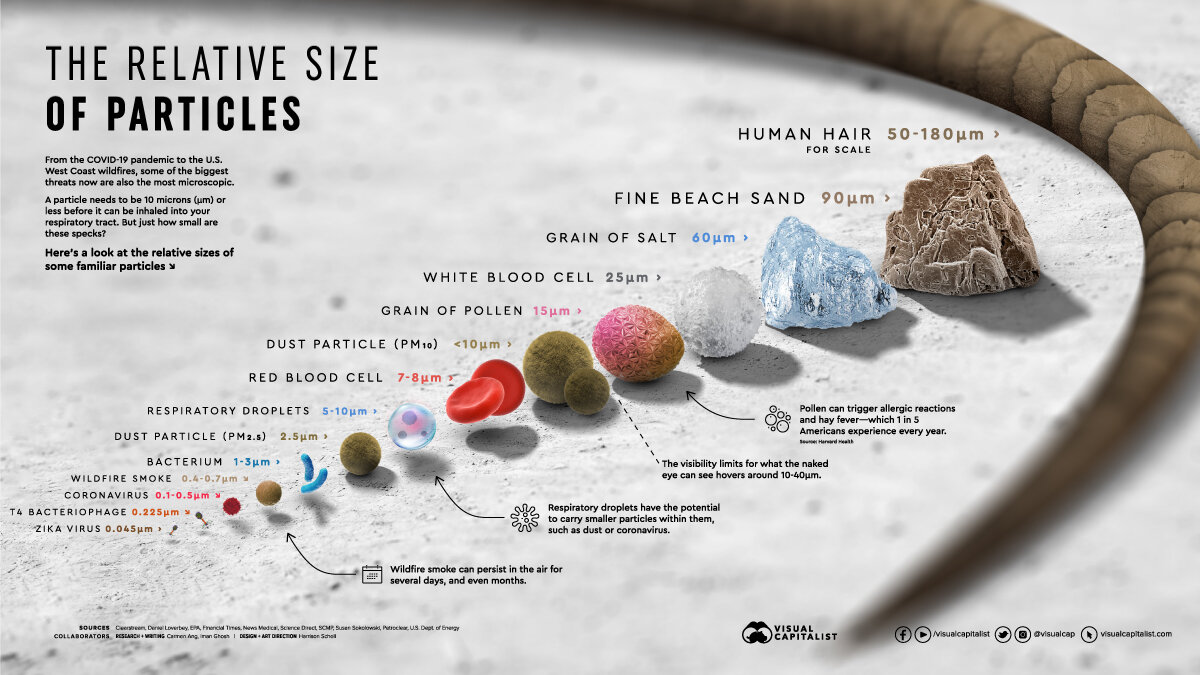

What happens in the chemical cleaning process? In simple terms, chemical cleaners bind to very small portions of deposit. Eventually, small portions are surrounded by the cleaners, suspended in fluid, and are carried away. Rates of binding can be increased by increasing the temperature and moving the bound deposits away. The detergent molecules have two key parts to them. One component that favours deposits, and the other part that mixes well with a fluid carrier. It is very important that the cleaning chemicals mix well with the surrounding fluids. Without adequate mixing, the transfer of heat and agitation will not allow continuous cleaning. An example would be trying to clean dishes without water but using soap alone. This mixing happens on the molecular scale (1.0x10-9 meters), or about one thousand times smaller than a micron (1.0x10-6 meters). Because of the small scale that cleaning occurs, chemical cleaning is a good choice when cleaning moving parts with tight tolerances.

How do chemicals clean deposits from internal engine components? This question arises quite often in the automotive fuels and lubricants industry. However, the explanation can be simplified with basic chemical and physical concepts we use every day. For example, many of us are familiar with the common household chore of washing clothing. If we wish to remove a particular type of stain from our favourite shirt, a few physical and chemical requirements need to be met.

HEAT

This seems to be a relatively well-known concept, but how can it be explained? Heat is a form of energy, and when added to a particular system (washing machine, dishwasher, engine crankcase), it allows greater probability for physical and chemical reactions to take place. Deposits may become soluble or dissolved in the water physically, or they may have the energy needed to chemically bind to some added laundry soap. Either way, adding heat improves the probability of substances interacting, which is necessary in cleaning.

Increasing the temperature of a system typically yields better results in cleaning.

When considering cleaning the internal components of a motor vehicle, heat is especially important when cleaning. Motors in automobiles are appropriately named “heat engines” in the engineering world because of their ability to convert heat into energy. Much of the heat is lost inefficiently in the process, but few mechanical systems are perfect. Some of this leftover heat causes the breakdown of fuels and lubricants into undesired deposits. If we wish to clean these deposits efficiently, using heat is a great way to increase our probability. Heat will improve the ability of deposits to be soluble in their respective fluids and provide energy for chemical interaction with compatible detergents.

When servicing vehicles, most mechanics make use of heat to clean their internal systems. Removal of deposits is a crucial part of ensuring mechanical parts move freely and without hindrance. Most services involving BG Products tools, equipment, and chemistry use heat to yield successful results. Ensuring deposits stay soluble and that BG chemicals are activated to remove them cannot be efficient without plenty of thermal energy. Be wary of cheap solvent-based cleaners over the counter. These products can evaporate easily when under heat and do not survive long enough to clean in most modern vehicle systems.

CHEMICAL

In most circumstances, the use of chemicals greatly assists in cleaning and removing unwanted substances. Cleaning agents typically don’t undergo a permanent chemical change but rather bind to deposits temporarily. Consider the previous example of dirty laundry. Washing clothes with soap (detergent) binds and suspends particles in the water. The dirty water is then drained, and we are left with clean articles. A chemical reaction hasn’t necessarily occurred where you end up with something different.

An ideal cleaner should not hinder the system, only interacting with the deposit.

With the permission of the content owner.

We also understand that chemical cleaners have an ideal time and place. Chemists have developed specific detergents that are compatible with unique deposits. You wouldn’t use dish soap to wash your hair or bleach on the carpet. Each type of chemical cleaner has been tailored for its purpose, as have detergents for deposits in automotive systems. Cleaning fuel and oil deposits in automotive systems require specific cleaning chemicals that are safe for their systems and effective on deposits.

As systems change in mechanical operation, so too do the types of deposits that they form. Using incorrect or outdated cleaning chemicals in these systems may yield no results or even potentially contribute to the deposits instead! Oil detergent cleaners should hold deposits in suspension, so they are removed with the old oil. In contrast, fuel detergent cleaners bind and move deposits to catalysts for oxidation. BG Products utilize the latest detergent technology tailored for fuel and lubricant systems used in the automotive industry.

SAE Technical Paper 2019:-01-2356: The Investigation of the Structure and Origins of Gasoline Direct Injection (GDI) Deposits.

AGITATION

It seems that the best lubricant in any industry across the globe is the tried-and-true concept of “elbow grease”. Before the advent of specific chemical cleaners, manual cleaning was the norm. Many systems make use of physical agitation to assist in their cleaning process. Too much agitation can cause damage instead of cleaning. A pressure washer too strong may remove not only dirt and grime but also paint from a surface. Ideally, the cleaning process uses agitation to increase deposit surface area for chemicals and heat to interact with. Moving deposits with agitation is helpful but needs to be done in a slow and safe manner.

The age-old method of physical agitation assists in the removal of deposits.

What agitation is provided in the air, fuel, and oil systems in vehicles to clean deposits with? Engine induction and exhaust systems make use of agitation with the flow and turbulence of air that passes through them. Air is a fluid that can be used to move and clean deposits. Fuel and oil are also fluids that provide flow, turbulence, and contact with deposits in their systems. The key to safe and effective cleaning of air, fuel, and oil systems is to make use of these existing engineered forms of agitation. Many services that implement BG tools and chemicals take advantage of existing levels of engine agitation in their cleaning procedure. Following the procedures outlined by BG’s automotive engineers ensure effective cleaning of deposits in a safe manner.

Deposits bound in oil are suspended and dispersed until they are drained out during service. Fuel system deposits are bound to detergent when contacted with treated petrol or diesel. Some of the chemistry only becomes activated with combustion. The combined airborne deposits are moved to catalysts where they are oxidized into harmless exhaust gases. Slow and gradual removal of deposits ensures that the catalysts are not overburdened or become blocked. As cleaning ensues, the combustion process becomes more efficient and further improves. Agitation is required to remove deposits from the system once they are bound to cleaning chemicals.

WHY CHOOSE BG PRODUCTS?

Aside from heat and agitation that occurs naturally in automotive operation, choosing BG Products should be on the topic of chemistry. Although there are many choices for chemical cleaning providers, few are so well-equipped. Maintaining ISO certifications ensure that the quality and selection of chemicals deliver results without harm. Many of these same types of chemicals are used in the manufacture of fuels and engine oils. Oversight from the EPA also ensures that the chemicals are well known and registered. These same families of chemicals are in use every day by Original Equipment Manufacturers (OEM’s), who do not manufacture their fuels and lubricants.

Working with OEM’s to solve deposit-related problems has earned BG a place in several TSB’s for a variety of different brands. Using retail store solvents to clean deliver minimal results and sometimes create problems. Professional trade-only chemistry is tailored to mix well, clean safely, and prevent future deposits. Using BG chemistry ensures that oil and fuel specifications are complemented rather than diluted. Modern vehicles have demanding physical and CHEMICAL demands that must be met for safe and effective operation. With thousands of dealerships and independent workshops partnered, BG Products maintains safe, effective, and trusted results.

Air, oil, and fuel passages have been engineered to function with minimal restrictions. The increasing demand for near-perfect flow in vehicle fluid systems has little tolerance for acceptable operation in the latest vehicles. Today, it has no longer become a matter of “if” internal engine components need to be cleaned, but rather “when”. The “what to use” portion of automotive cleaning has a major impact on the effectiveness of services that use cleaning chemistry. And the effectiveness of chemicals, in turn, have an impact on a mechanic’s good or bad experience with such services.

KEY ITEMS FOR REVIEW:

Heat

In chemical cleaning, heat is your friend, up to a point. Thin solvents don’t survive long enough to clean much when heated. Make use of professional chemistry that can survive modern fuel and oil system temperatures and pressures.

Chemical

Not all chemicals are created equal; look for brands that have credentials in quality, manufacturing, or partnership with OEMs. Modern fuel system cleaners are specialised in either petrol or diesel. Fuel products that claim to do both use outdated technology and may promote deposits.

Agitation

Use procedures according to manufacturer instructions when performing chemical cleaning. Products that do not dilute specifications or additive packages prevent mechanical damage when cleaning.

-Clinton J. Meyer

ACS Certified Petroleum Chemist working for BG Australia.

BG Products Inc.

BG Products, Inc., the leading manufacturer and supplier of automotive fuel and oil conditioners, specialty chemicals, greases, tools and equipment, is ISO 9001, 14001, 17025 and 45001 certified.

As an ISO Certified company, BG Products, Inc. is obligated to provide transparent and factual information. All products are tested and proven to provide added benefits to equipment owners.

If you want to learn more about our products and services you can contact us here.